What is laminate?

Laminate is a surfacing material for furniture and interiors, made using multiple layers of kraft paper and resins.

The surface layer consists of decorative paper printed in a woodgrain or material design, or a solid colour. This is known as the decor, or decorative finish. To protect the print and heighten abrasion resistance, a transparent overlay is added on top of the decorative paper layer in woodgrain and material decors. Beneath the surface are several layers of unprinted kraft paper. These layers make up the core of the laminate.

All papers are resin impregnated and pressed under high pressure and heat to form a solid, thin laminate sheet. The sheet may be a range of thicknesses, with a common industry thickness of 0.8mm.

The laminate sheet material may be classified as a CPL (Continuous Press Laminate) or HPL (High Pressure Laminate) – both are common industry terms frequently used in connection with laminate and relate to the manufacturing process of each type. In both cases, the resulting material structure and performance testing requirements in accordance with industry standards are identical. Both produce a resistant laminate with the characteristics mentioned later in this article.

How is laminate used?

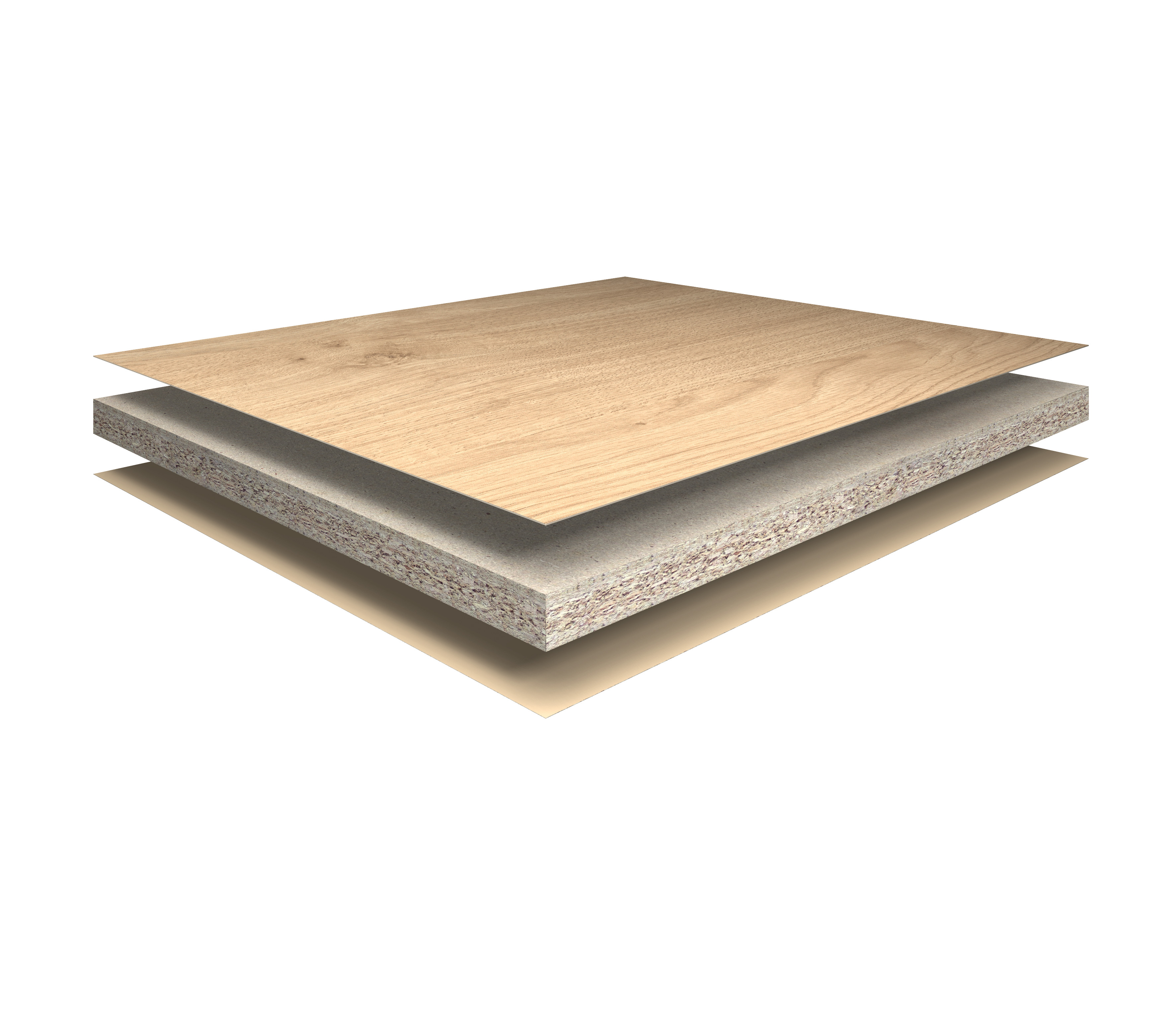

To use a laminate in interior design it must be bonded to a suitable substrate such as chipboard, MDF, plywood or lightweight panels. A balancer must be applied to the reverse side of the substrate.

This process in referred to as laminate bonding or laminating. This process produces a laminated panel or structure suitable for use in joinery and furniture fabrication.

What are the benefits of laminate?

Laminate is a versatile surfacing material suitable for variety of applications. It’s flexible format means it can be bonded to curved or shaped surfaces with ease, including cylindrical forms and pillars, opening up artistic design concepts. This makes laminate particularly appropriate for creatively designed retail counters, reception desks and display fixtures.

Laminate surfaces are highly resilient, and ideally suited to commercial interiors where furniture surfaces can commonly see heightened wear, as well as domestic applications such as kitchen worktops or vanity units.

At EGGER, extensive testing of our laminate surfaces demonstrates further resistance to impact, abrasion, scratches and stains. These properties mean they can withstand heavy use on high traffic surfaces, such as reception desks, retail counters or tabletops in bars and restaurants, without deteriorating.

Laminate surfaces are lightfast, meaning they stay true to their colour over time, even in direct sunlight. They are also moisture resistant, non-porous and antibacterial in accordance with ISO 22196. This test results certifies that EGGER laminate surfaces achieve the highest level of reduction of two common bacteria types, Escherichia Coli (E-Coli) and Staphylococcus Aureus, over a 24 hour testing period in stringent testing conditions for temperature and humidity. As a result, our laminate surfaces are particularly suitable for interiors in the healthcare and hospitality sectors.

Find the perfect laminate solution for every design application in the EGGER Decorative Collection 24+ .

Where should designers specify laminate?

Not all interior surfaces call for the resilience to heavy use that laminate provides. For example, mid to low traffic applications such as table bases, wall panels or furniture end panels, even in commercial spaces, see less surface wear, meaning that the characteristics of laminate may be a technical over specification in these areas. Choose laminate for applications that see particularly heavy use, prolonged impact or recurring wear such as reception desks, retail counters, booth seating, and bar and table tops.

Does your design scheme also include low and mid traffic surfaces? Choose an alternative material such as Eurodekor Faced Chipboard, a decorative faced panel, for these areas. This will allow you to achieve the desired end result with less costs for material and labour.

What is the difference between laminate and decorative faced panels?

Laminates and decorative faced panels differ in composition, manufacturing process and suitable use. Both offer unique advantages, characteristics and limitations.

We have discussed that laminate is a thin surfacing sheet material made from impregnated paper layers and resins, and must be bonded to a substrate for use in interior design.

Decorative faced panels are wood based materials, supplied in panel form with a standard industry thickness of 18mm. Thicknesses of 8 - 38mm are also commonly manufactured. The panels comprise of a wood based core layer that is faced with decorative paper on both sides.

The wood based core of a decorative faced panel may be constructed from chipboard or from Medium Density Fibreboard (MDF). When faced with decorative paper, our chipboard panel becomes Eurodekor Faced Chipboard, which has a common industry term of MFC, while decorative faced MDF uses the term MFMDF. While the core material differs, the surface material and characteristics are shared.

Similarly to laminate, the decorative paper layer on both sides of a decorative faced panel is made from impregnated paper and is pressed to the core layer under high heat and pressure. A number of characteristics are shared with laminate including resistance to abrasion, scratches and stains, lightfastness, moisture resistance and antibacterial properties.

Decorative faced panels are ready to cut and edge into smaller panel components for furniture pieces, such as drawer fronts, cupboard doors, cabinets and end panels. No additional processing is required.

Decorative faced panels are robust and hard-wearing, and particularly suitable for low to mid use surfaces in commercial spaces, and almost all applications in residential spaces.

Eurodekor Faced Chipboard (MFC) is one of the most cost effective and versatile materials available in furniture and interior design. In residential interiors, student accommodation and hotel guestrooms, MFC is commonly used for kitchen units, frontals, wardrobes, bed bases, headboards, shelving, desks, wall panelling and fitted furniture. Its versatility is met with some limitations, as MFC can not bend or be curved. It is therefore suitable for straight sided furniture pieces only.

How does this impact project costs?

While material costs will vary widely depending on finish type, decor and texture, and manufacturing process, it is important to keep in mind that laminate requires bonding to a suitable substrate, and as a result incurs additional costs for a substrate material, balancer and labour.

An understanding of these material differences can help keep product specifications relative to the application, and avoid the unnecessary cost impact of over-specification. To learn more about this process, read our guide to value engineering in construction .

Support

This article is for informational purposes only. If you are searching for the information about specific EGGER products, please visit our knowledge hub .